At our factory test centre, we are quite busy. Our export of propeller pumps across the world is high. We are finalising propeller pump orders for Azerbaijan, Singapore and Norway right now, to name a few. All pumps are quality tested in our test basin before final delivery to the customer.

Test Centre

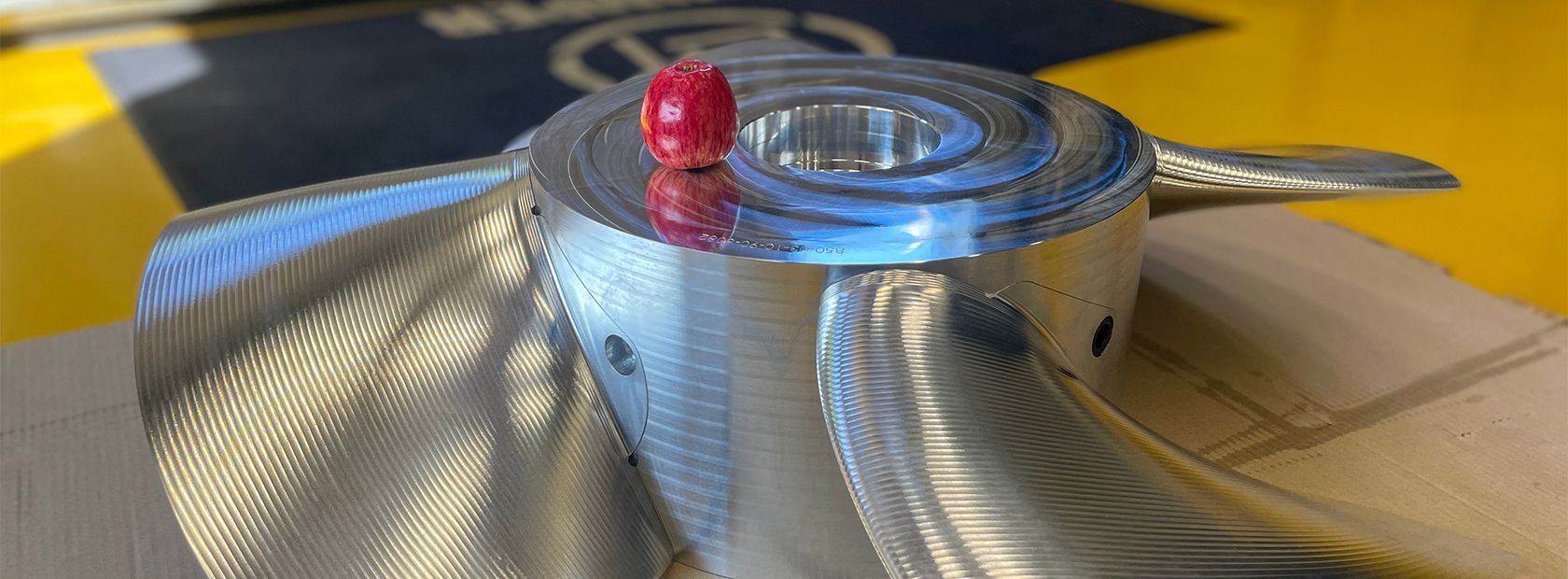

Running the propeller pumps through continuous tests is key to our development process. Since we produce pump solutions customised to each individual customer exclusively, we have established our own Test Centre to perform physical test running of our pumps. Our engineers and constructors test all pumps in collaboration with our technicians before they are sent to the customer.

The unit consists of a tank divided into two sections with separate installations for steel and HDPE pumps. An important unit element is the integrated advanced flow metering equipment we use to measure pump capacity and efficiency. The unit holds approx. 1 mill. litres of water in total.

Our Test Centre is also used for testing complementary pump solutions, and the facilities are made available to various public institutions and business partners, too.

Azerbaijan: LMPump FRESH for process water – industry filtering. PR 200 – 350 m3/h.

Singapore: LMPump SALT. Aquaculture – kingfish farm. Reverse return pumping in closed system, in a flow-through farm. PR 400/500 PE – 1700 m3/h.

Norway – Salmar: LMPump FRESH. Aquaculture – salmon farm. Pumping of drainage water. PR 400/500 – 1550 m3/h.

Testing of a pump for Norway – Salmar: LMPump FRESH PR 400/500 1550 m3/h.

1. “Salmar_Norge_Testcenter”

STAY UP TO DATE!

Sign up for our newsletter to receive our inspirational stories. You will hear from us a couple of times a year.