Several fish farms have ordered extra pumps so that they have both when they need to do service and in case of an accident

Three pumps have been sent out into the world in recent weeks. Two to a large fish farm in New Zealand and one to Norway. The pumps have one thing in common: they are a kind of "insurance pumps". Understood in the sense that they are extra pumps that the fish farms need to be able to use when the existing pumps need to be serviced - and if the unfortunate event occurs and there is a breakdown.

An extra pump provides safety for the fish.

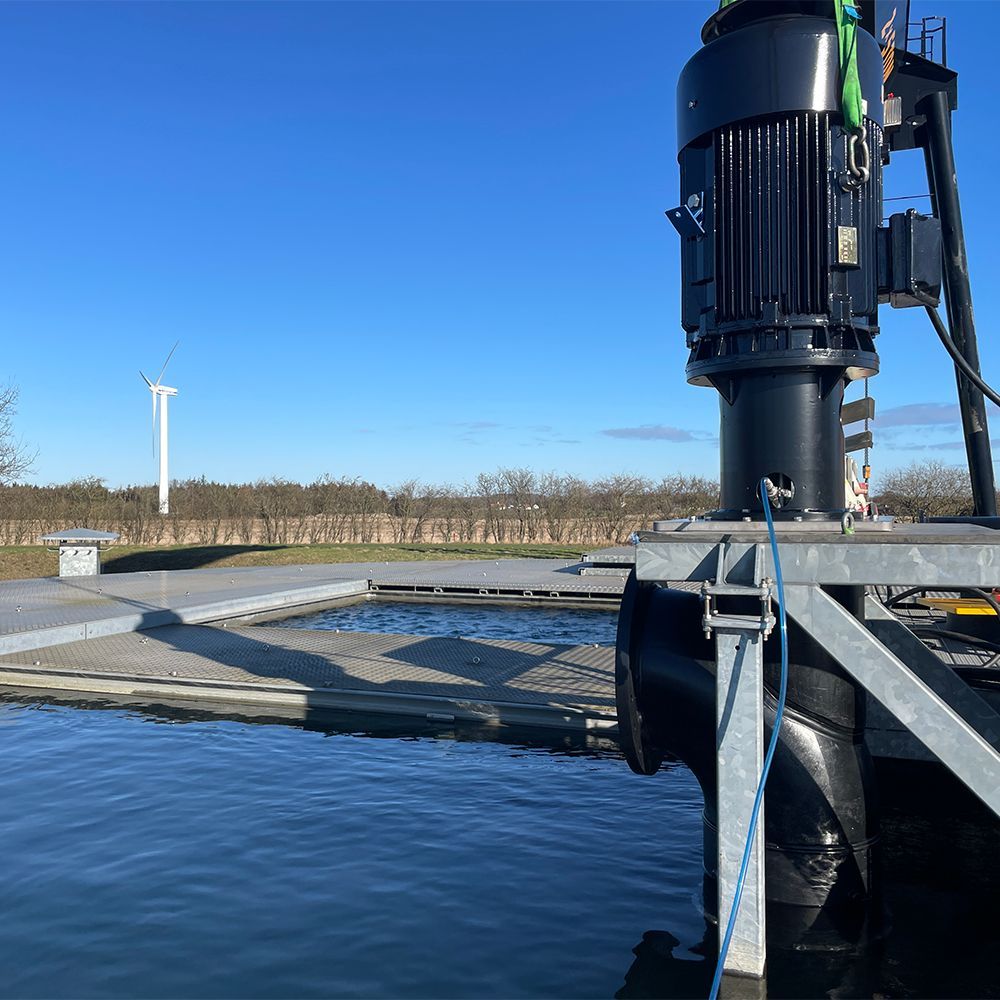

Norske Ænes Inkubator AS is very, very dependent on their pumps working all the time. Because the fish in their farm will die after just a short downtime. This applies not only to them, but to the vast majority of our customers in the fishing industry.

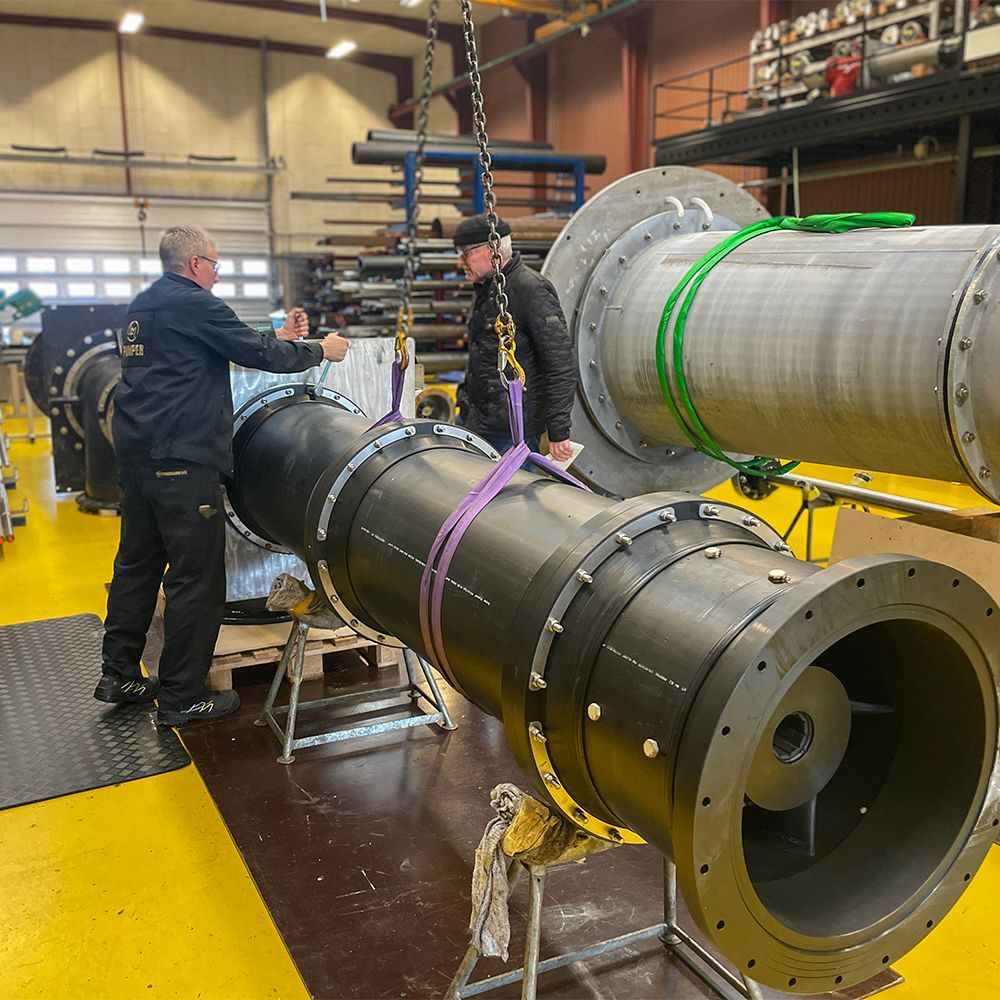

The company opened in 2022 - and was completely finished in February 2023. At that time, we delivered eight pumps for their ponds. Now, to be on the safe side, they have ordered an extra pump exactly like the other eight. And a delegation from the factory has just visited Lykkegaard on Funen to be trained in how they can maintain and carry out minor repairs on the pumps themselves.

So if there is an accident and one pump fails, they can quickly switch to their backup pump and have the other repaired without compromising the well-being of the fish.

It's a bit like driving around with a spare tire in the car.

Fish insurance for New Zealand

Three years ago, we delivered eight new HDPE pumps to a new RAS fishing facility in New Zealand. As with the Norwegian facility, it is absolutely crucial that the pumps run constantly.

Now it is time for the first service inspections of the pumps. In this connection, the company has ordered two pumps identical to the first eight. Then they can take their time and remove two pumps and insert the extra pumps, while the technicians carry out service and minor repairs.

The extra pumps also act as insurance if there is an accident and a pump suddenly fails. Then you can quickly insert a spare pump and save the fish and the facility.

The pumps are of the LM Salt PR 400/500PE type and have a propeller diameter of 400 mm.

They are essentially identical to the eight we sent over three years ago. However, the propellers on the new pumps have been updated. In the meantime, we have switched from having the propellers cast in Sweden to milling them on our advanced CNC machine here at the factory. This shortens production time, avoids CO2 emissions from transporting the mold and the cast propeller, and in addition, the finished propeller no longer has to be polished, which previously released metal dust.

Extra pump for norwegian fish farm

Extra pumps for fish farm in New Zealand

STAY UP TO DATE!

Sign up for our newsletter to receive our inspirational stories. You will hear from us a couple of times a year.