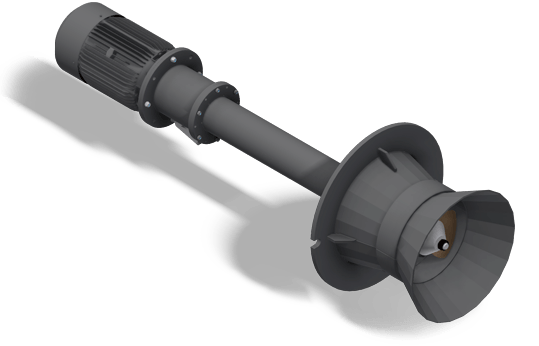

OTHER ADAPTED SOLUTIONS

In addition to manufacturing propeller pumps of the highest quality, we also have substantial expertise in manufacturing related products for the pump industry. Often these are tasks that require flexibility, a quick reaction and an understanding of the needs of the customer.

EVERY PUMP IS TESTED

Quality does not only concern the manufacture of pumps. We are of the opinion that quality is a result of using thethe idea of low operational and maintenance costs as a starting point and then dimensioning the pump solution.

Dimensioning is not only a question of pump size. It is an essential element of our quality assurance and documentation process that among other things concerns compliance with the requirements of national and international machinery directives as regards traceability, preparation of inspection forms and descriptions of operations for machined blanks as well as 100% acceptance checks and component control in the production.

Before our pumps are finally handed over to the customer they undergo extensive tests and quality assessments. We perform practical physical tests in a basin with test tools and programmes that ensure that all tests are performed in a true-to-life environment.

Pumps for export are delivered in closed boxes with full traceability of the shipment.