Did you know that 99% of a pump from Lykkegaard A/S can be reused or recycled? And that we offer to disassemble old pumps and sort the parts so that they can be reused as best as possible? This is how we have always done it - but now it has become modern to relate to reuse and recycling.

In 2022, we bought 38.5 tonnes of steel – and sent 36.5 tonnes for recycling. This is not because we have such a large amount of waste in our production - but rather that 2022 was a year in which we repaired and restored many old pumps and in that context helped the customers with the parts that could no longer be used in the pumps. Some of the new pumps we produced were in HDPE material and others were built from pump parts from stock. So it is not every year that we end up purchasing and recycling almost the same amount of steel.

But the numbers are now interesting anyway.

At Lykkegaard, we have gone through a course in Dansk Industri's project Climate-ready Production Company. We have done this because we receive training in preparing

our CO2 accounts and become aware of how we use resources and which ones we use. It is necessary because several customers demand it in connection with large projects. It also gives us a more detailed knowledge of our own emissions.

Optimizing resource consumption and recycling has always been high in Lykkegaard's value chain – climate accounting or not. For generations, we have produced pumps with the goalog using the least possible power to move exactly the amount of water that the customer demands.

In this content, we have also sorted our waste into as many fractions as we could think of, so that we can recycle it the best possible. Some pump parts we can reuse directly ourselves, as when we quickly repaired an older drain pump with a pipe part that we had saved from a previous pump. However, it is not often that we are so lucky.

We often take the pumps apart into as small parts as possible and send it for recycling - divided according to the type of metal it is. There is an economic advantage in this, because we simply get more money for the metals we send for recycling if they are as clean as possible. But it also has a great environmental advantage, because it can be recycled exactly as it is – steel, duplex, aluminum or brass.

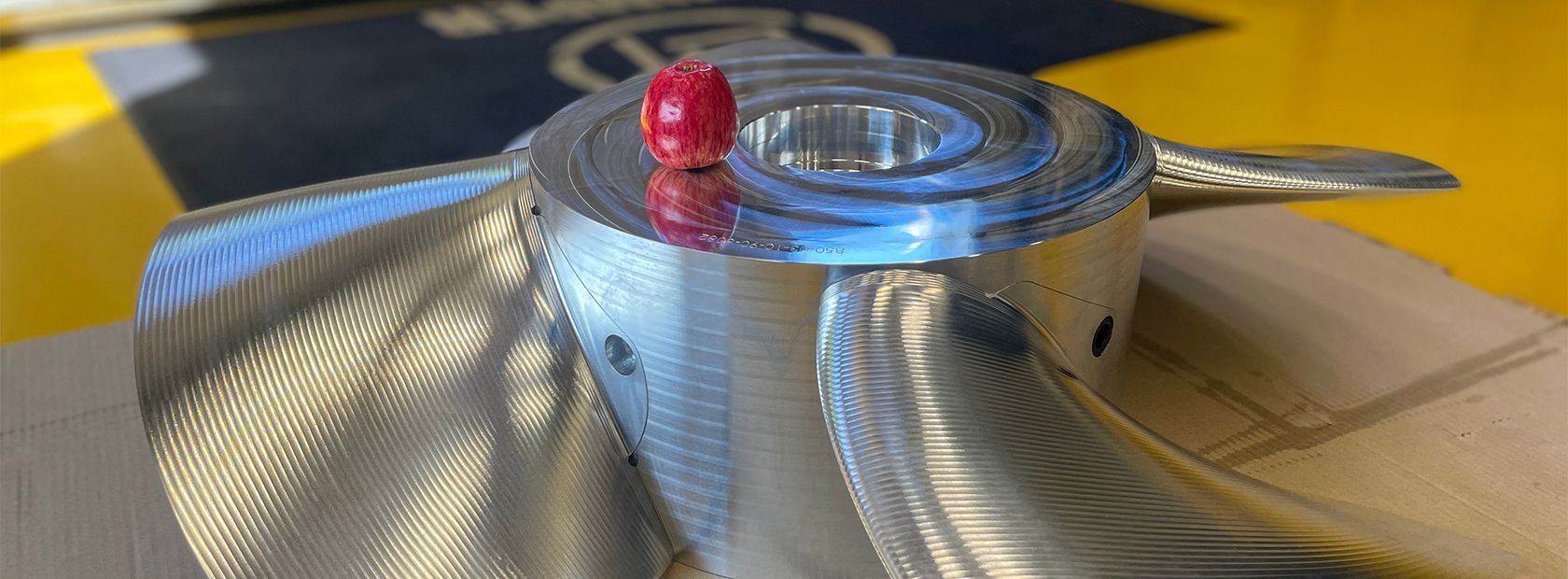

Lykkegaard's pumps are produced so that they can be taken apart and reused as much as possible. In fact, it is only a rubber bearing that sits as a shaft bearing inside the pump, which cannot be reused directly from pumps that usually weigh several tons.

"It makes good sense for us to know what kind of materials we are working with. And a clear conscience that we know that it can all be separated and reused again. It could

when my grandfather built pumps many decades ago - and we have no reason to change that. Now it has become so modern to be able to say that everything we make can be recycled. So now it's as if the old-fashioned has become modern," observes Karsten Lykkegaard.

STAY UP TO DATE!

Sign up for our newsletter to receive our inspirational stories. You will hear from us a couple of times a year.