Lykkegaard has repaired and restored one pump for Odense Harbour's large dry dock. So now the dock can once again function at full power

One of the two dry docks at the Odense Port has lacked capacity for a period, when one of the three large pumps that pumps the water out of the dock broke. The shaft was broken and several pump parts were broken in that connection.

It is a huge pump, which weighs up to eight tonnes and can pump 2500 liters per second, and can therefore quickly empty the dock when a ship has sailed in to arrive at the shipyard.

At Lykkegaard, we were asked to repair and restore the pump so that it is ready to run again. And preferably as soon as possible, so that the dock does not have to stand for too long.

Design of special parts

The pump is so large and different from the pumps we normally work with, so special drawings were needed. Unfortunately, there were no finished drawings of the individual parts for the pump (It is not Lykkegaard, which produced it in its time. If it had been, we would have had the original drawings).

Therefore, we had to measure and design ourselves based on the damaged parts and produce new ones that fit the size. A demanding detail work for engineers and industrial technicians. Because on such a pump, everything must fit together down to 1/100 of a millimeter.

"It has taken time and been demanding. But it is also a challenging task that gives professional pride when it works," says Uffe Holtze, who is an industrial technician and has worked with pumps at Lykkegaard for 26 years.

He has had the professional responsibility in the workshop for the reconstruction of the pump. It is therefore also him who has turned the new shaft and all the newly designed pump parts.

Must be able to work in salt water

All pump parts have been taken apart in connection with the repair and it has been painted with a new layer of super strong composite, which can withstand working in salt water in the harbour. Steel will rust quickly, but with the glossy composite surface, the salt water cannot penetrate and therefore the pump can last much longer.

Now the pump has been picked up by a trucker and lifted onto the warehouse with Lykkegaard's largest crane and set in place in the dock at Lindø with the help of another giant crane. A few employees from Lykkegaard have been out to ensure that the pump is running as it should.

"It is an exciting and demanding task. But it also makes a lot of sense for us to repair and restore. Because even though we have spent a lot of working hours getting the pump to run smoothly again, it is still very time-saving compared to building a new pump - and far better for the environment that we recycle everything we can. The one we have delivered now is as good as new," says Karsten Lykkegaard, owner of Lykkegaard Pumper.

The pump as it arrived at Lykkegaard

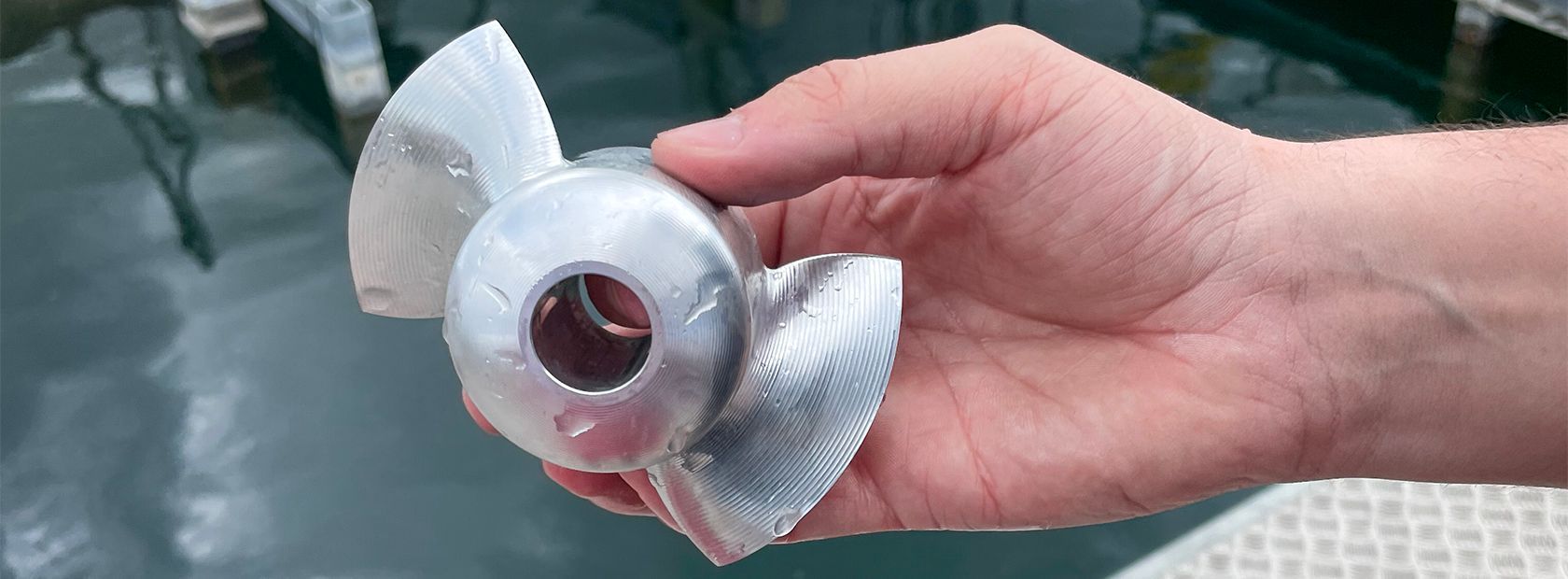

Processing the restored propeller

The pump after restoration

Timelapse of when the pump was picked up at Lykkegaard

STAY UP TO DATE!

Sign up for our newsletter to receive our inspirational stories. You will hear from us a couple of times a year.

We will get back to you as soon as possible.

Please try again later.

PRODUCTS

SERVICE

We offer maintenance and repair of our products and pumps from other suppliers. We also provide quality consultancy concerning selection of the perfect solution.

CURRENT TOPICS

CONTACT

LM Lykkegaard A/S

Nyborgvej 35

5863 Ferritslev

Denmark

Tlf. +45 65 98 13 16

Fax +45 65 98 15 65

WHAT ARE YOU LOOKING FOR?

STAY UP TO DATE!

Thank you for signing up to our news letter

You will recieve our news letter when we'll send it out the next time

Please try again later.

© 2024 Lykkegaard A/S. Cookie policy -