The people in the city of Aarhus can be safe in the event of heavy rainfall. Especially those in Aarhus North.

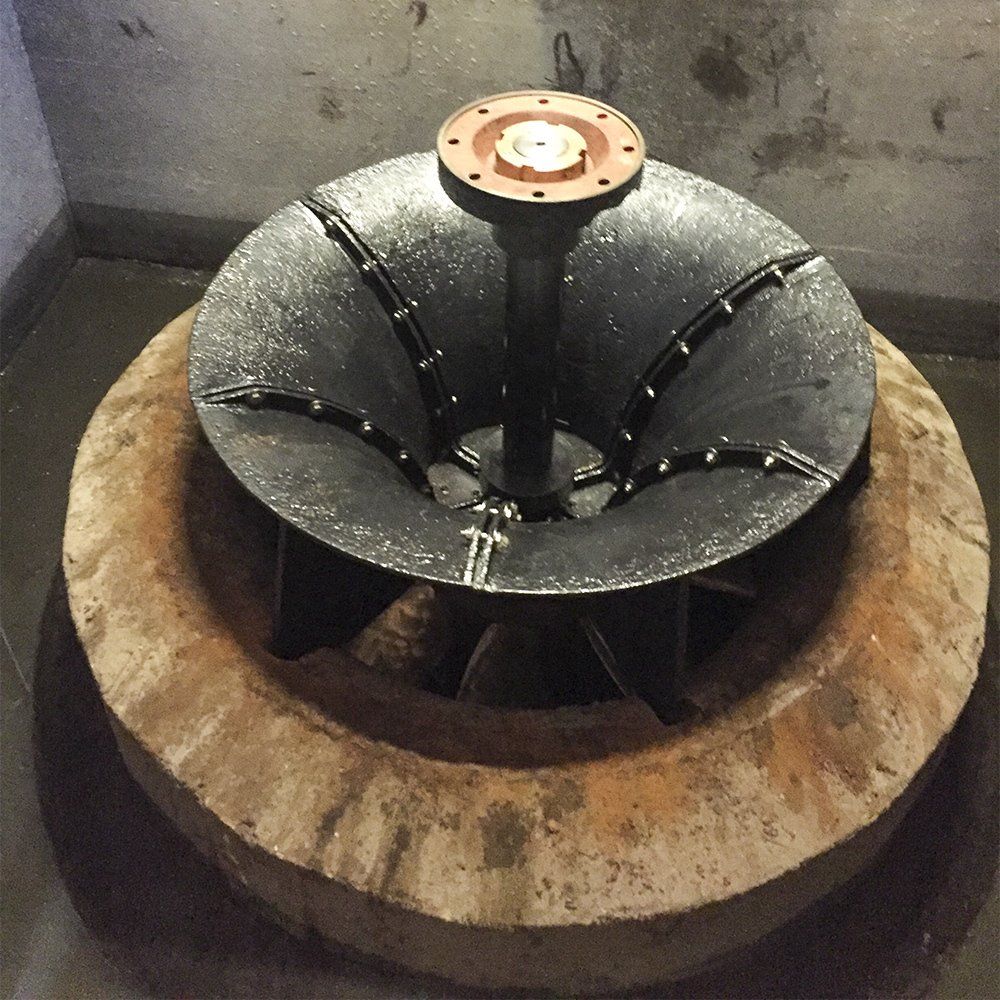

Lykkegaard A / S has recently completely renovated one of the two large pumps, which keep the area around Egå drained of water. It can pump 4000 liters of water per second, so it can really move huge masses of water, if there is a cloudburst or a period of particularly heavy rain in the area.

Lykkegaard A / S has recently re-installed one of the two drainage pumps, which direct rainwater away from the township of Egå and the rest of Aarhus North. Summer and heavy rains can now come without causing an overload of the pumps. Each pump can remove 4000 liters of water per second, if the amount of water in the area require it - though it is really rare that both pumps work at highest level at the same time.

This spring, one of the two very large pumps that drain Århus Nord, broke down and a thorough restoration was needed. Lykkegaard A / S has performed service on the pumps for more than 30 years, for this reason we were also chosen to fulfill the task of repairing the pump.

In addition to the broken axel which was the reason for the crash, the propeller blades had gradually become so worn, that they were too short and had to be extended. The guide vanes that lead the water to the propeller, were all in a bad condition - and most had rust holes.

The wooden counter flaps, which ensure the water does not run back, when the pumps are switched off, had rotted. So they were completely replaced and Lykkegaard has built new ones that fit the measurements of the particular pump house.

Reuse and repair support sustainability

Lykkegaard's philosophy is to repair and reuse as much of the existing material as possible, when we renovate and provide service. Sometimes building new woould be easier and more economic favorable to us as a company.

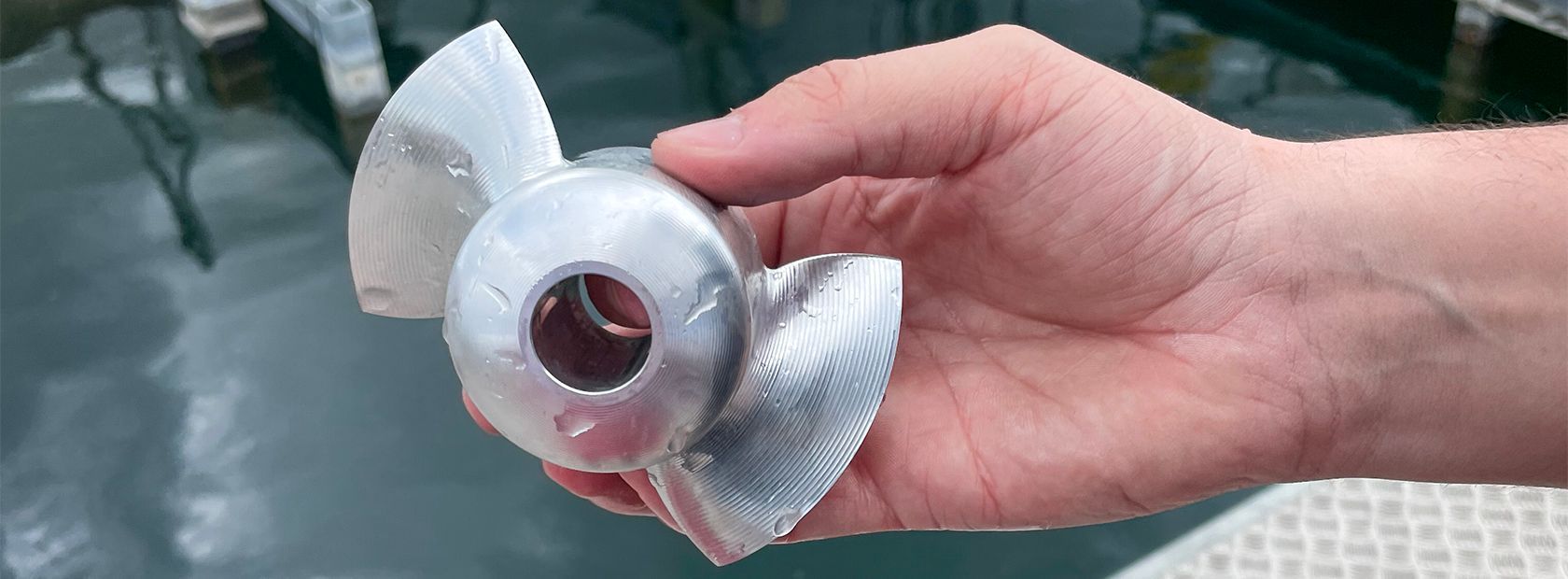

It is deffinitely easier to cut or grind too much, than to add extra lenght to propeller blade. So it has been a challenging task in the workshop to expand the diameter of the propeller by welding an extra piece on and then adjusting it to the angle and thickness of the part old part.

We succeeded apart from fact that we had build two brand new counter flaps instead of the rotten ones, and that we produced a new axel, all parts of the pump have been recycled and repaired, so the pump is now running as good as a new one.

“It is a fun task to work with because we are challenged on something we do not do every day. But there is also a great satisfaction in handing over a pump that runs optimally and where we have used the craftmanship to recycle so much material and repair it! ” says Karsten Lykkegaard, who owns Lykkegaard A / S.

Pictures from before the restoration

From the process

-

The propeller blades has been

Button -

The propeller with the extra lenght visible

Button -

Niels assures the messurements are correct

Button -

Producing a new giant nut for the axel

Button -

Building new giant nut for the axel

Button -

The ned Axel is measured

Button

Building the brand new counter flaps

ButtonSTAY UP TO DATE!

Sign up for our newsletter to receive our inspirational stories. You will hear from us a couple of times a year.

We will get back to you as soon as possible.

Please try again later.

PRODUCTS

SERVICE

We offer maintenance and repair of our products and pumps from other suppliers. We also provide quality consultancy concerning selection of the perfect solution.

CURRENT TOPICS

CONTACT

LM Lykkegaard A/S

Nyborgvej 35

5863 Ferritslev

Denmark

Tlf. +45 65 98 13 16

Fax +45 65 98 15 65

WHAT ARE YOU LOOKING FOR?

STAY UP TO DATE!

Thank you for signing up to our news letter

You will recieve our news letter when we'll send it out the next time

Please try again later.

© 2024 Lykkegaard A/S. Cookie policy -